Working with resin can be incredibly rewarding, but getting a flawless finish starts before you even pour a single drop. In this guide, we’ll take you through the essential steps to prepare your workspace, mold, and resin so your projects come out smooth, bubble-free, and professional-looking.

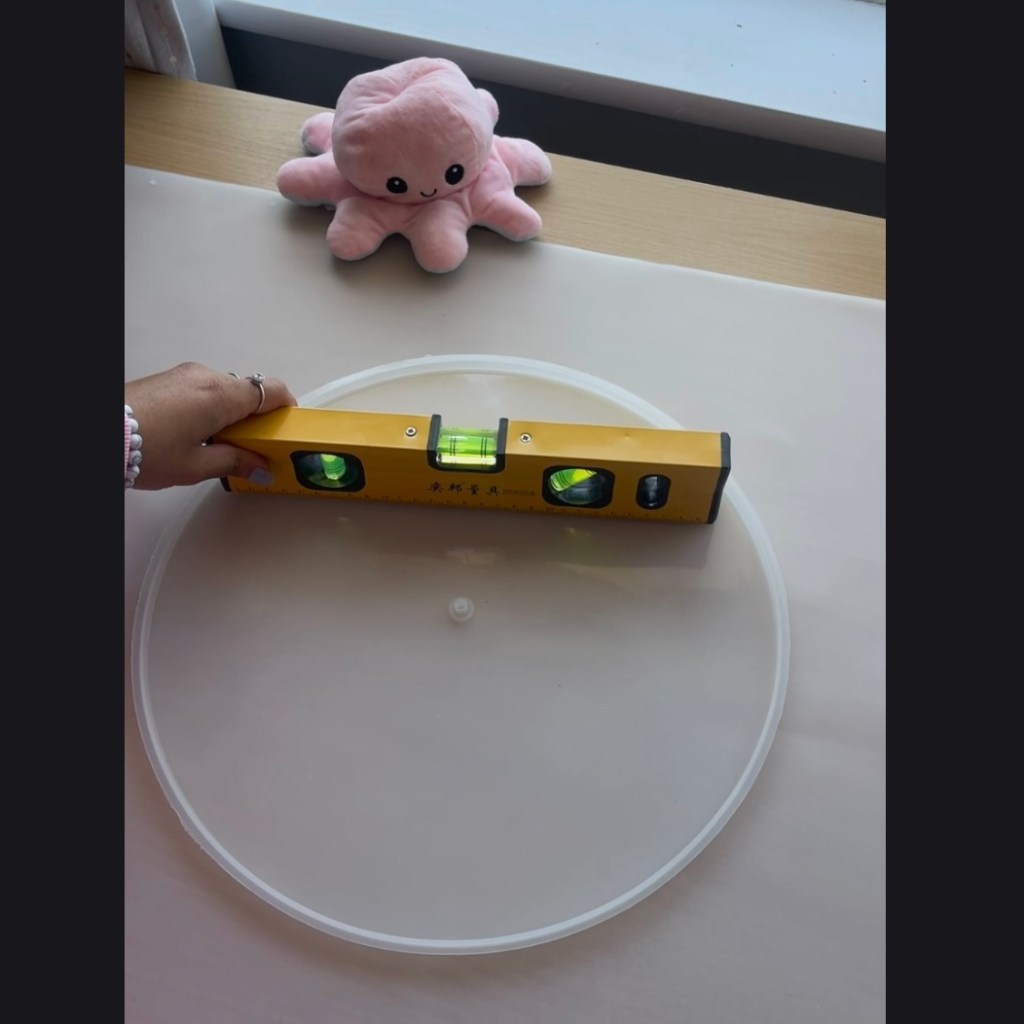

Step 1: Choose a Stable, Level Surface

A level surface is the foundation of a perfect resin project. If your table or workspace is uneven, resin can pool in certain areas, leaving one side thicker than the other.

Tips:

- Use a flat, stable table.

- Place protective sheets or parchment paper under your mold to catch any drips.

- Check with a spirit level if possible, especially for larger projects.

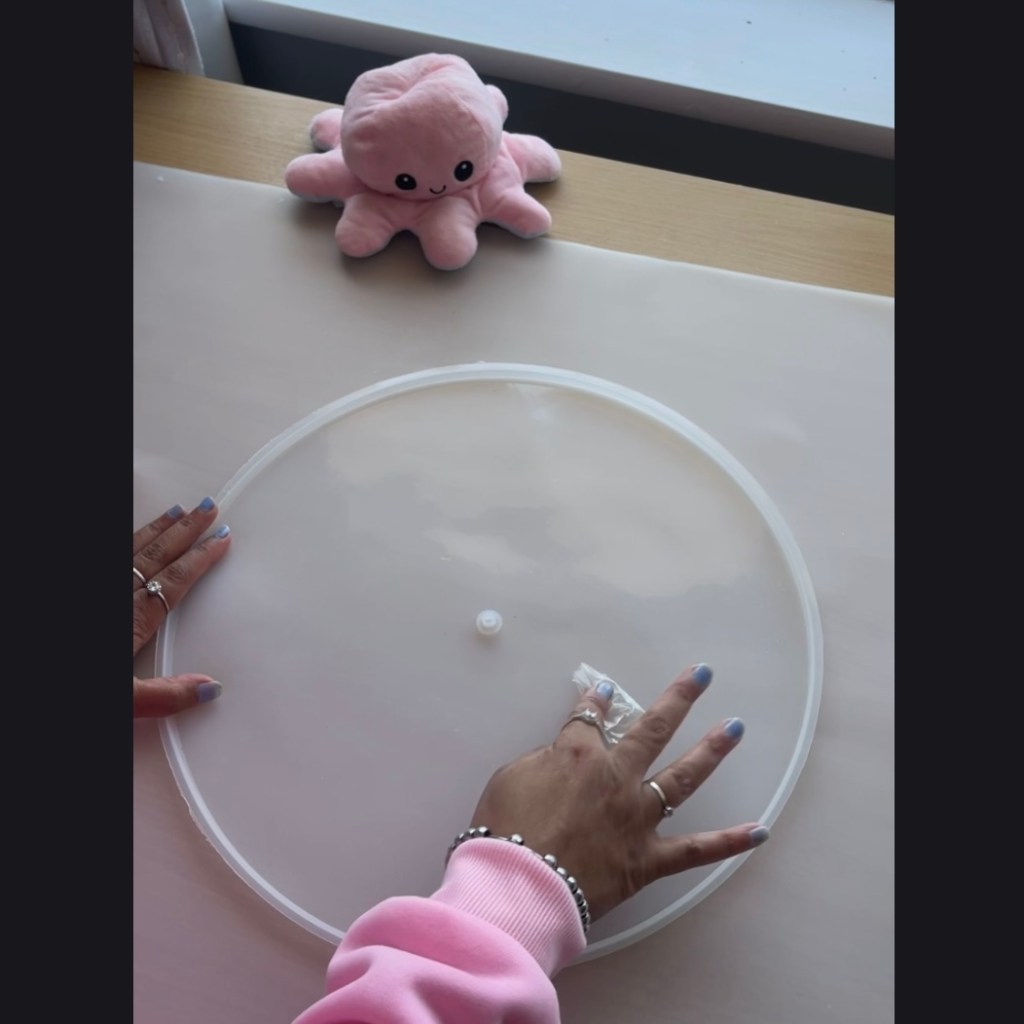

Step 2: Clean Your Mold Thoroughly

Even the tiniest dust or fingerprints can show up in resin. Cleaning your mold properly ensures a crystal-clear finish.

Steps:

- Wipe the mold with a lint-free cloth.

- Use cellotape or masking tape to lift away tiny particles.

- Ensure the mold is completely dry and free from oil or residue.

💡 Pro Tip: Silicone molds can be wiped with isopropyl alcohol for extra cleanliness, but let them dry completely before pouring.

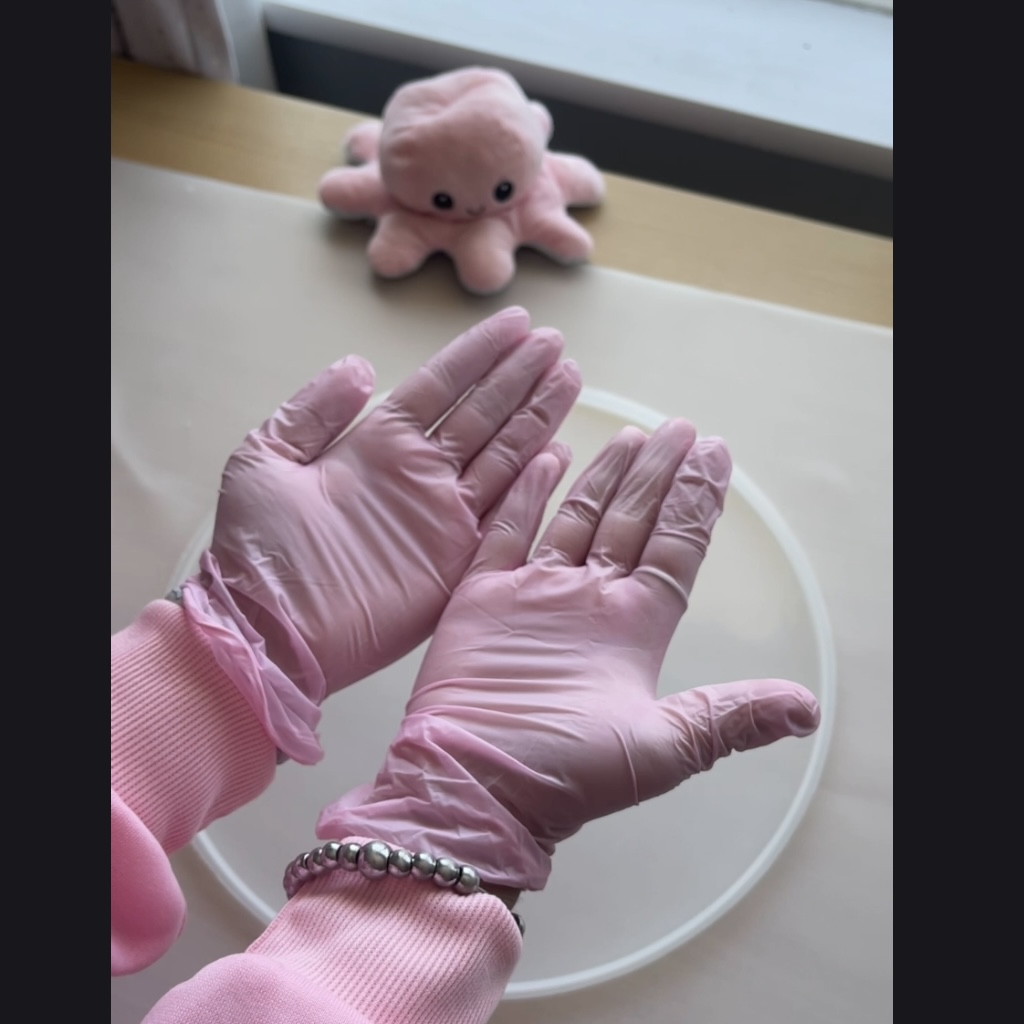

Step 3: Wear Gloves and Prepare Safety Gear

Before handling resin, protect yourself and your workspace. Safety gear helps prevent skin irritation and keeps your environment clean.

Steps:

- Put on nitrile gloves to protect your hands. (Avoid latex gloves—they can react with resin.)

- Wear a mask if you’re working in a small or poorly ventilated area.

- Keep paper towels or cleaning wipes nearby for spills.

- Cover your workspace with a plastic sheet or silicone mat for easy cleanup.

💡 Pro Tip: Always work in a well-ventilated area and keep food and drinks away from your workspace.

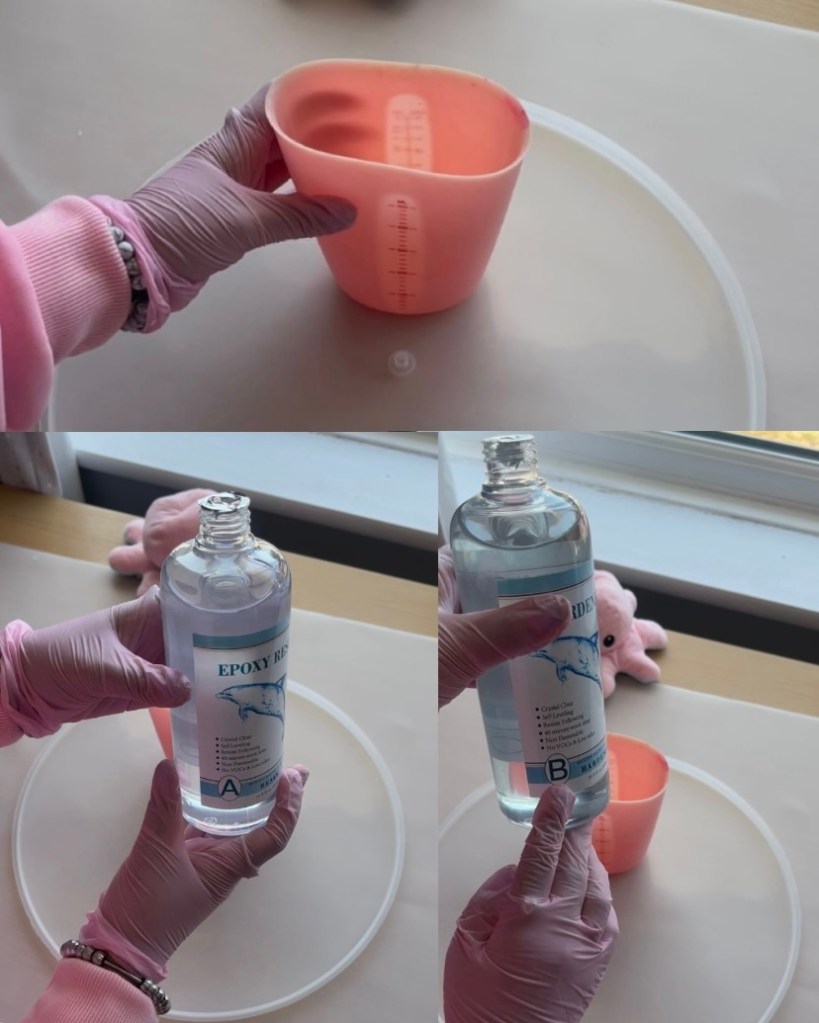

Step 4: Measure Resin Accurately

Resin comes in two parts: Part A (resin) and Part B (hardener). Mixing them in the correct ratio is crucial for proper curing.

Steps:

- Check the manufacturer’s instructions for the exact ratio (e.g., 1:1 or 2:1).

- Use separate measuring cups for Part A and Part B.

- Pour carefully to avoid spills and maintain precision.

💡 Pro Tip: Always measure by volume, not weight, unless the instructions specify otherwise.

Step 5: Mix Resin Thoroughly

Mixing ensures that Part A and Part B react properly. Improper mixing is a common cause of sticky or uncured resin.

Steps:

- Pour Part B into Part A.

- Stir gently but thoroughly for at least 2–3 minutes.

- Scrape the sides and bottom of your mixing cup to make sure everything combines.

💡 Pro Tip: Mix slowly to reduce bubbles, but don’t rush—thorough mixing is essential.

Step 6: Optional Workspace Preparations

- Remove dust from the air or cover your project with a box or plastic sheet.

- Have a heat gun or torch ready to remove surface bubbles after pouring.

- Double-check your workspace lighting so you can see bubbles and details clearly.

Conclusion

Preparation is the key to perfect resin projects. Spending a little extra time on leveling, cleaning, and mixing ensures your pieces come out clear, smooth, and professional every time.

Final Checklist Before Pouring

- ✅ A level workspace

- ✅ Clean, dry mold

- ✅ Gloves and safety gear on

- ✅ Accurately measured resin parts

- ✅ Thoroughly mixed resin

- ✅ Bubble-removing tools ready

✨ At Krafty Ash, we believe every creation tells a story. Get your workspace ready, stay patient, and let your creativity flow!

Leave a comment